SO-100-YF Gripper

Version: 1

Date: 14/05/2025

Designer: Yovan Fowdar

Organization: Mauritius AI Community

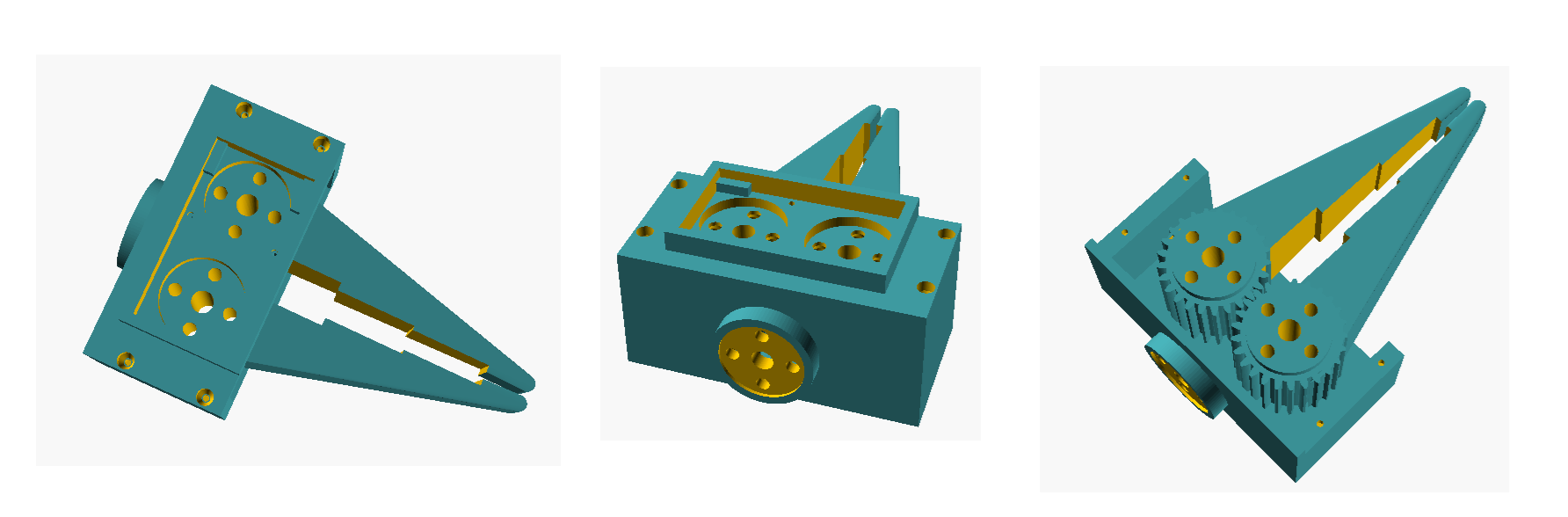

Overview The SO-100-YF Gripper is a simple, symmetrical claw-style robotic gripper designed as an alternative to existing solutions. It is inspired by and based on the LeRobot project https://github.com/huggingface/lerobot.

Demo Video https://www.youtube.com/shorts/Frp9GneYD9w

This gripper features:

Symmetrical claw closure for balanced gripping

Compatibility with ST3215 servo motors

A gear-driven mechanism that eliminates the need for additional fasteners (beyond those supplied with the servo)

The servo mounting plate is directly attached to one claw, and motion is transferred to the second claw via integrated gearing. For improved grip, it's recommended to line the claws with soft or spongy material.

Assembly Steps

- Place the servo ST3215 on the Upper Case

- Secure it with 2 small screws

- On the left claw attach the servo metal plate and secure with 4 x M3 screws

- Place the 2 claws in the Lower Case in a gripper closed position

- Place the Upper Case on top of the Lower Case , making sure that gear of the plate slides in the servo shaft gear. (you might need to move the claws slightly)

- Secure the Upper Case on the Lower Case with 4 small screws

Features

⚙️ Gear-based symmetrical claw movement

🧩 Lightweight and easy to integrate into robotic arms

License

This project is licensed under the MIT License. You are free to use, modify, and distribute it, with attribution to the original author.

STL Files & Licensing All STL files included in this repository are released under the MIT License, and are open to improvement, remixing, and customization. Community contributions are welcome—feel free to modify the design, adapt it for your use case, and submit pull requests.

TODO

Add a camera mount attachment to the servo motor body

Upload an assembly video

Enhance the aesthetics with rounded corners

**Version 2 ** Please use file 4- Claw-Left- V2.stl it is taller and is now more suitable to reach the ST-3125 servo metal drive disc, the holes for the screws have also been widen.