-

Notifications

You must be signed in to change notification settings - Fork 13

Build Guide (In Progress)

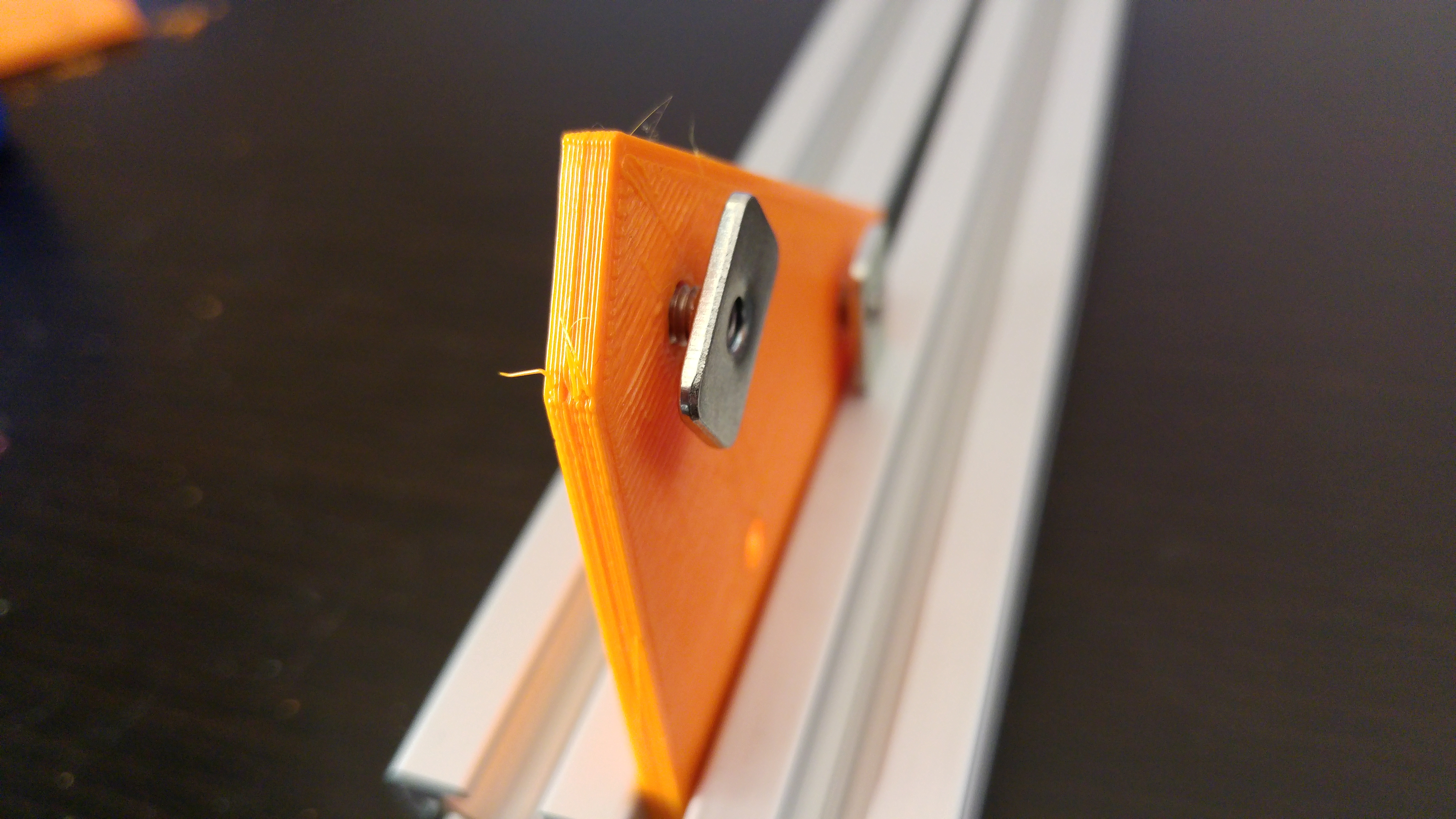

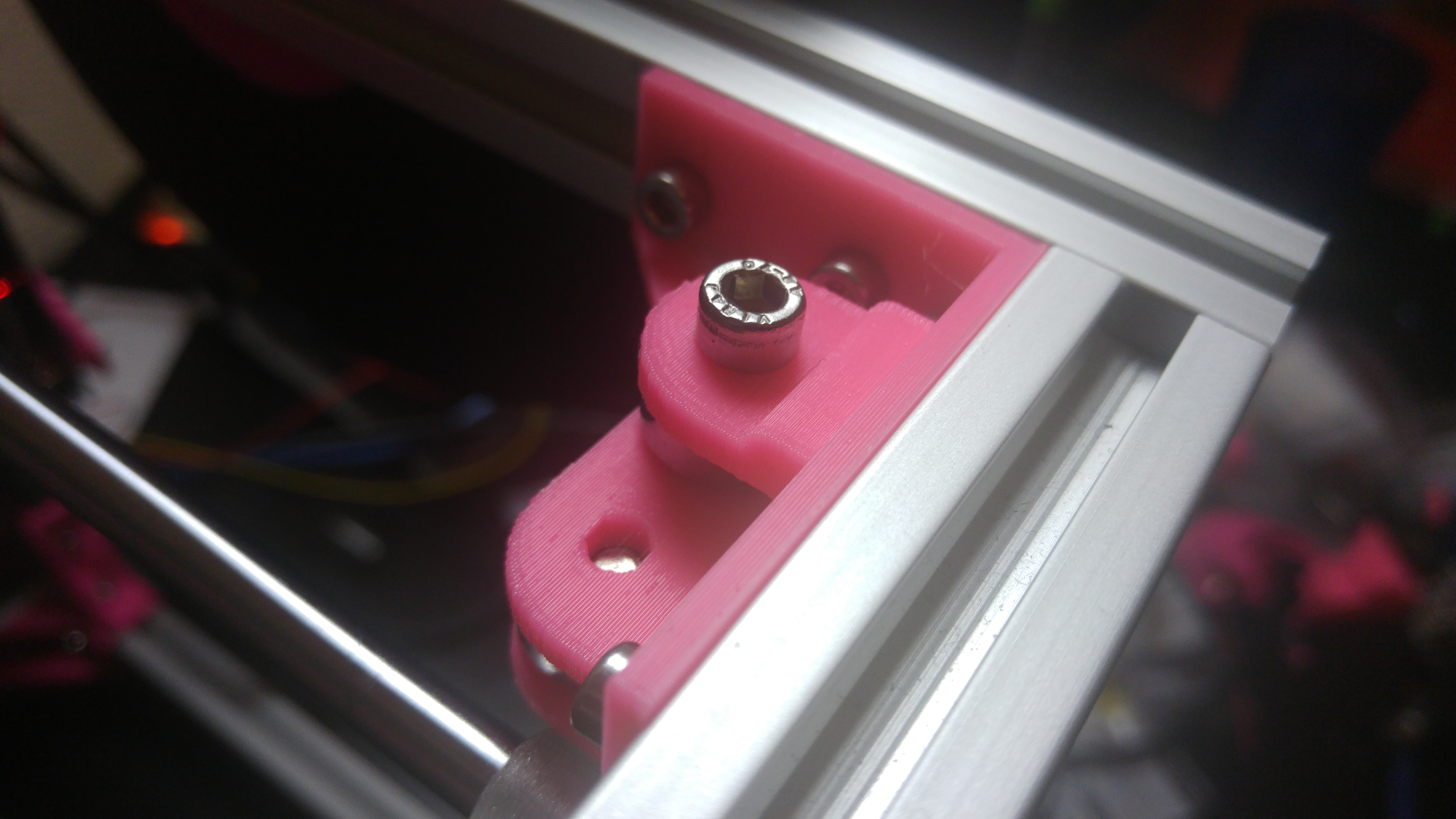

Pre-Assembly T Nuts are just that, they need to be added to the part before assembly like so:Pre-Assembly T Nuts are just that, they need to be added to the part before assembly like so:

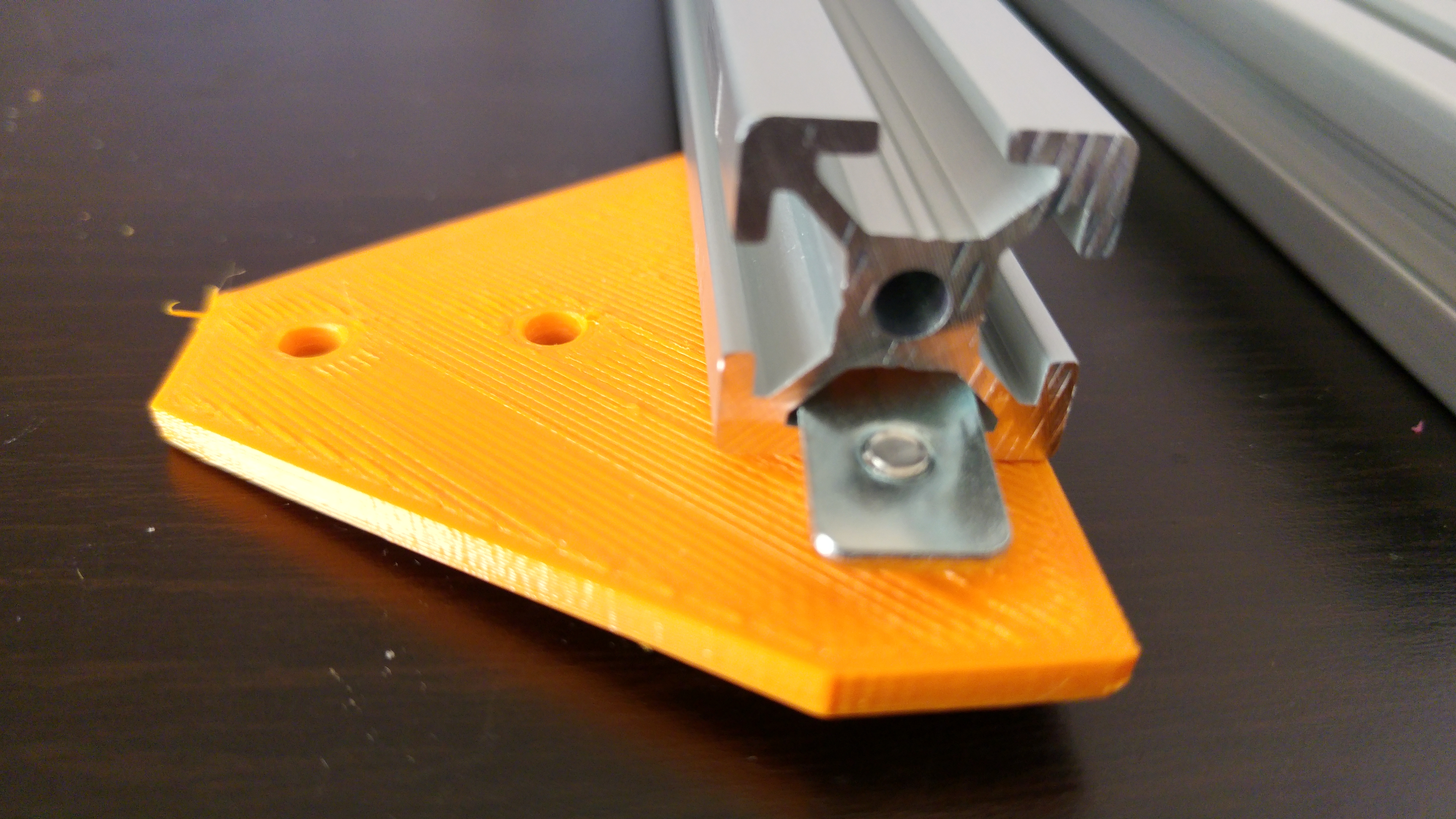

The part can then be slid into the extrusion and tightened:

All structural parts require the pre-assembly type of T Nut and 8mm M4 Bolts.

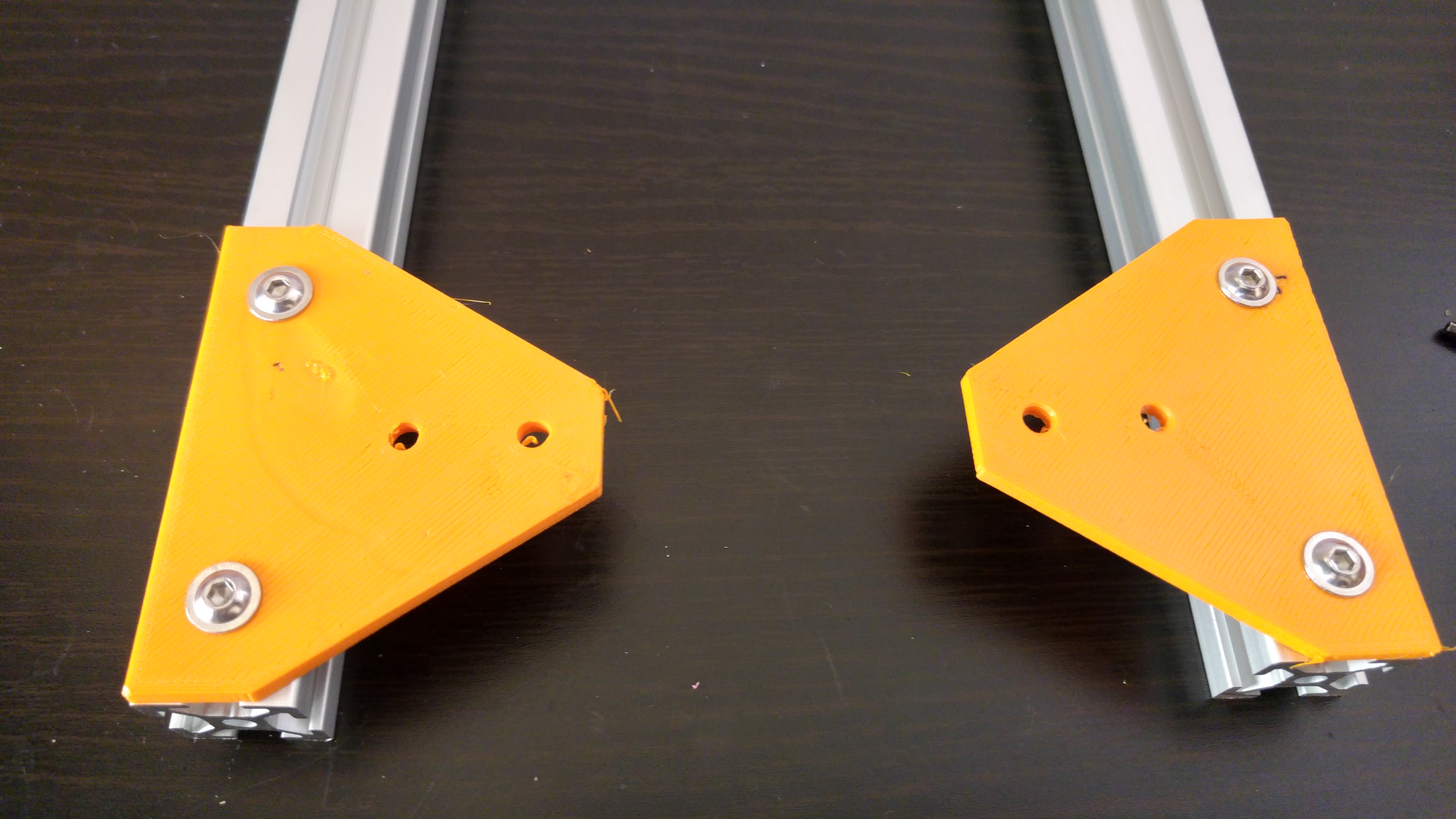

Take the 2 of the 345mm (FB2020 Standard) or 2 of the 445mm (FB2020 +) extrusions and slide the 2 of 4 bottom corner brackets in and tighten, one per extrusion so they mirror each other:

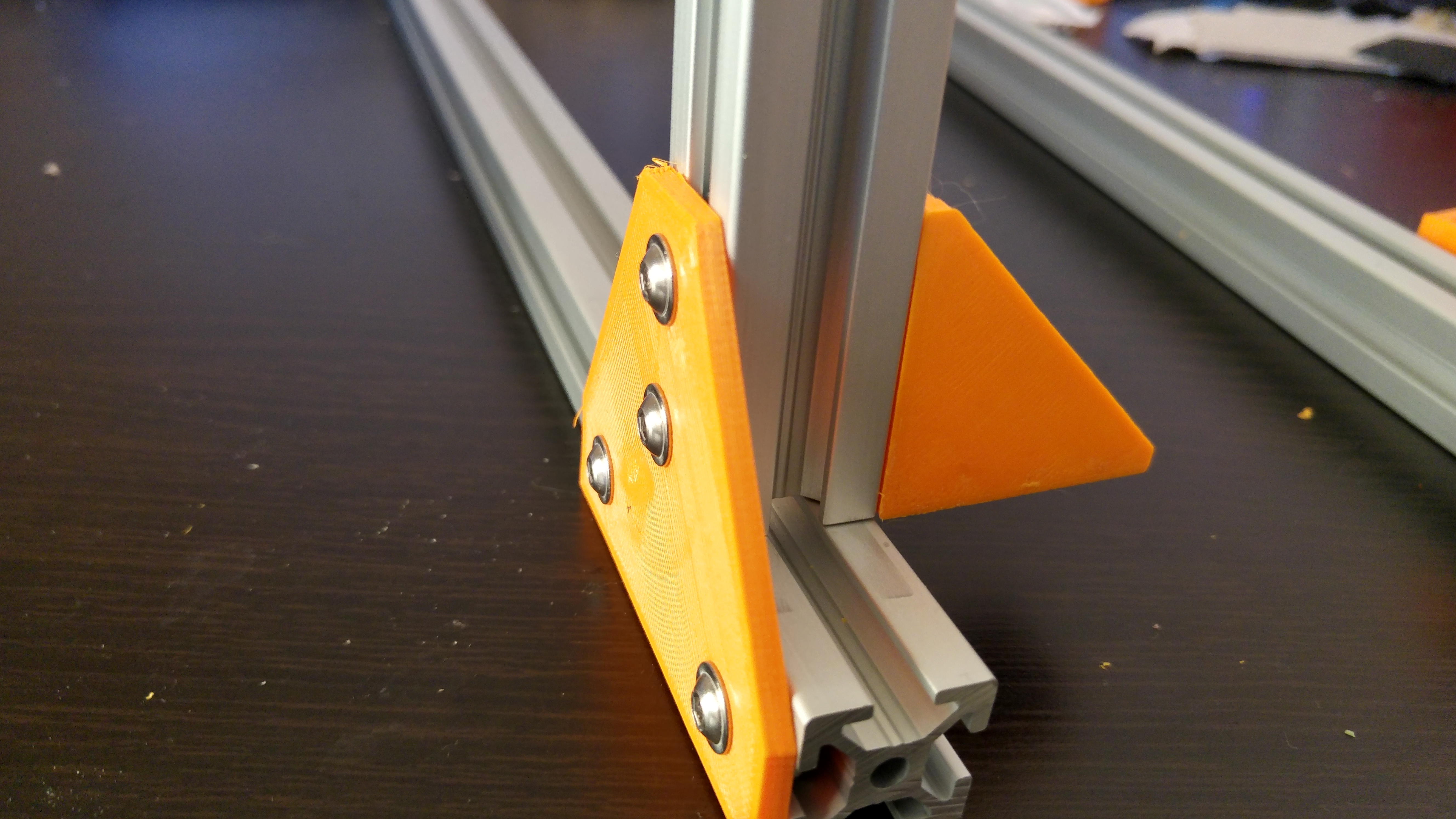

Next, take a 380mm extrusion and then place 2 corner brackets at each end, once again, mirroring each other. Slide one end of the 380mm extrusion into the bottom corner bracket with the corner bracket on the opposite side, making sure the extrusion butts up against the vertical one tightly, tighten the bolts:

Repeat this for the opposite end. You should now have a U shape.

Now take another 380mm extrusion and insert 2 corner brackets, once again mirroring each other with the opposite face of the bracket facing so it can slide into the top of the U shape. Next take the left and right idlers and slide them into the extrusion so they are facing away from the side the Bottom corner brackets face.

Do Not insert the bearings at this point as it will make it difficult to insert the T Nuts for the Y Axis Extrusions

Slide the corner brackets into the U shape frame so the bottom of the inserted extrusion is level with the top of the vertical ones.